Steering columns and components are safety critical. Rigorous and extensive testing ensures the long-term safety, quality, and performance of all GSS products. We consistently upgrade our test equipment. We implement critical safety procedures at the start of every project. We also test the materials, performance, and safety of all components and assemblies at every step of the process in our state-of-the-art full-service test lab. The result? Products that not only set the benchmark for strength, safety, and durability, but also align with the most modern and rigorous industry standards, marketplace trends, and user demands.

To support design and development activities, GSS engineers have extensive in-house testing capabilities at each of our facilities. GSS is continuously testing to support R&D, new program development, and production validation to ensure that our uncompromising standards of performance, quality, durability, and safety are achieved.

Quality assurance at every step

Ongoing performance testing

Assurance that all products meet performance, safety, and durability requirements

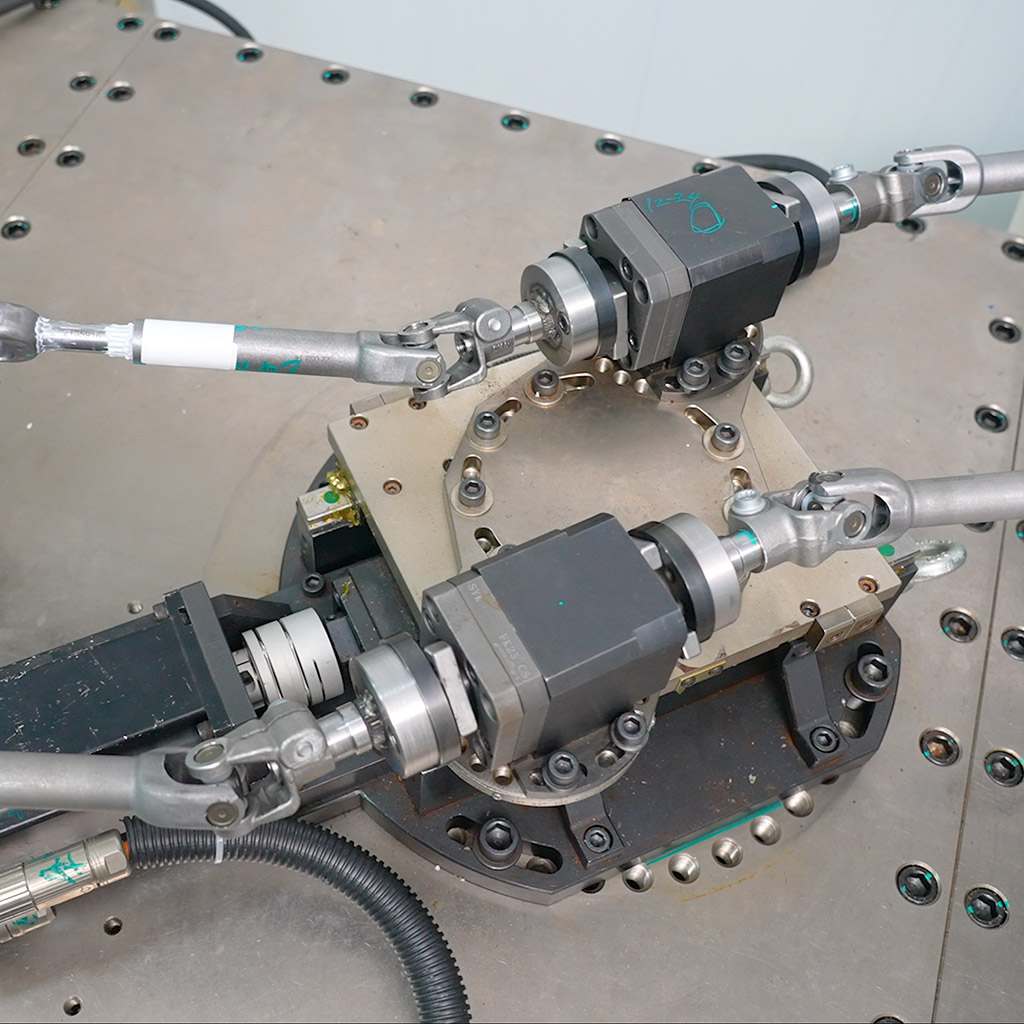

GSS employs a state-of-the-art, 4 specimen, Intermediate shaft test stand capable of duplicating Column EPS application conditions. The flexible computer controlled system can be programmed directly or via imported customer test profiles to ensure accuracy and the ability to duplicate exact conditions.

Continuous monitoring by this system provides accurate, real-time data to help strengthen and improve product development as demanded in an ever-increasing performance environment.